Our Facilities

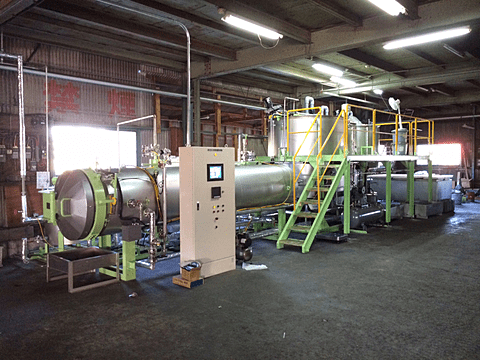

Low temperature biodryer

The dryer of the Nakamura sliced veneer introduces a biodryer drying a tree with a tree. Conventionally, by a heat source using the electric far infrared rays, I move water in the wood at low temperature of around 40 degrees Celsius and, not the drying by the high temperature using the fossil fuel seen well, dry it.

Characteristic of materials dried with a low temperature biodryer

- As it is low temperature drying, there are few materials breaking, confusion, curves and keeps strength.

- As I do not get a cell out of order, I keep a texture, luster, a fragrance.

- There are few change of color, corruption that there are not combustion, the oxidation of the lignin and shuts in organic acid (formic acid, acetic acid) as it is low temperature drying.

As I dry a tree with a tree, a dryer sucks in the water which evaporated.

As it is 40 degrees Celsius, I can easily check dry condition in a dryer.

Vacuum pressurization impregnation device

The impregnation tank contains wood to 4,200 millimeters in length.

I can pressurize liquid pressurization, two ways of air pressurization.

Projecting board cutter

A cutter to cut off a projecting board to necessary size.

I work carefully so that the width of the projecting board does not incline.

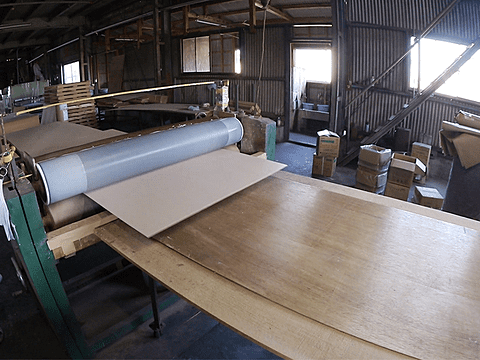

Paster

A machine to paste plywood, MDF.

I delicately regulate quantity of application with a projecting board or humidity to put.

Hot press

A machine to stick a projecting board on plywood.

I usually press it at 103 degrees Celsius. Press time is coordinated by a kind of a projecting board and the base material.

Wide sander

A grinder to finish the projecting board surface smoothly.

With care to overdoing of abrasion, I work.

Other facilities

Panel so (wood cutting processing machine)

Warehouse