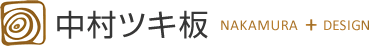

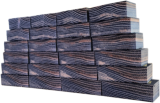

Dyed veneer

Dyed veneer - IRODORITAI VENEER-

Our Dyed wood / Dye penetrated wood IRODROTAI series, Dyed veneer are the totally new Dyed veneer that process of manufacture was reversed.

I dye it in the state of the plate called Frietchie to the wood inside and I slice it afterwards and process it into a projecting board.

(the Dyed veneer of the normally dyes it in a state of the Wood veneer after having sliced it.)

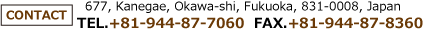

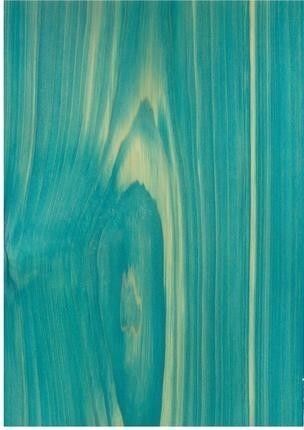

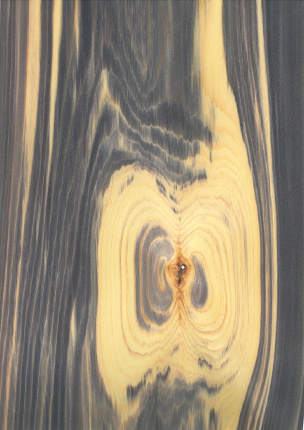

It is the greatest characteristic that by taking such a process, can get the Dyed veneer with the unique contrast and design like kintaro candy from the characteristic that dyestuff is hard to penetrate to eyes (annual ring part) in winter in succession.

In addition, there cannot be the thing that a color comes off even if I bend Wood veneer.

A cedar, a hinoki are available for the wood species.

Let alone the kneading on fire charge account to a plywood, woodwork art, DIY are available widely.

(*kyodeganchu*gan 2020-146606)

Wood species | It is maximum length | Thickness | Color |

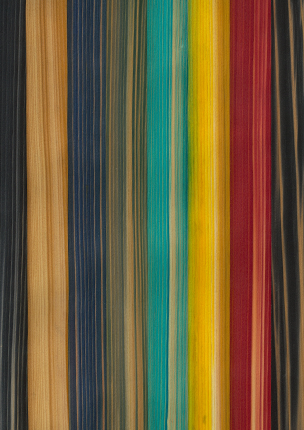

Cedar | 8 shakus (2,400mm) | 0.2 - 1.0mm | Black, blue, green, red, light blue, yellow |

Hinoki | 7 shakus (2,100mm) | 0.2 - 1.0mm | Black, red, light blue, yellow |

The maximum length mentioned above is just based on experience. The dyeing to the wood inside becomes difficult more, and the risk of the penetration irregularity increases so as that the dimensions of materials are long if long and are thick if thick.

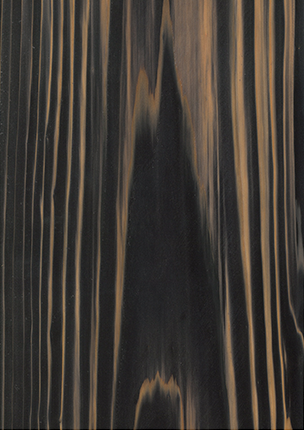

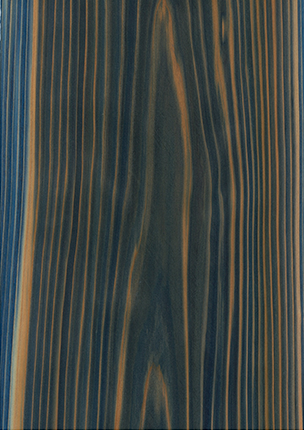

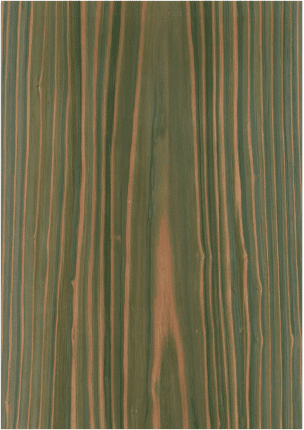

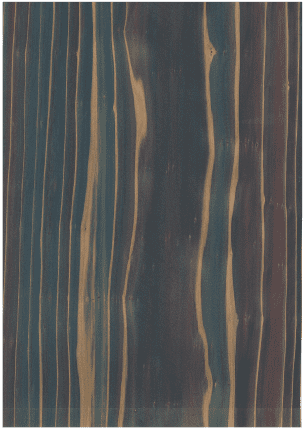

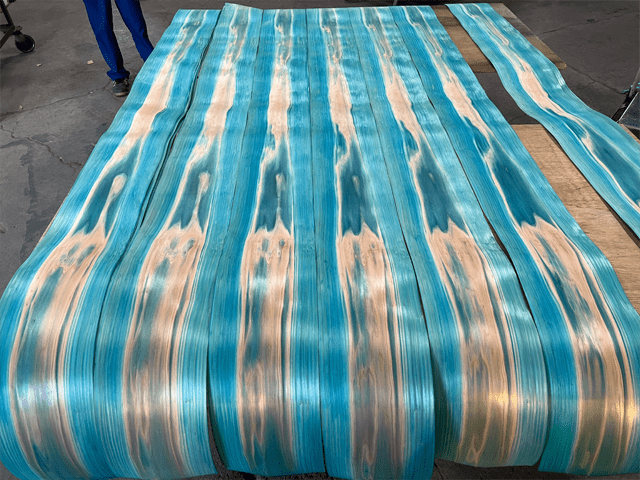

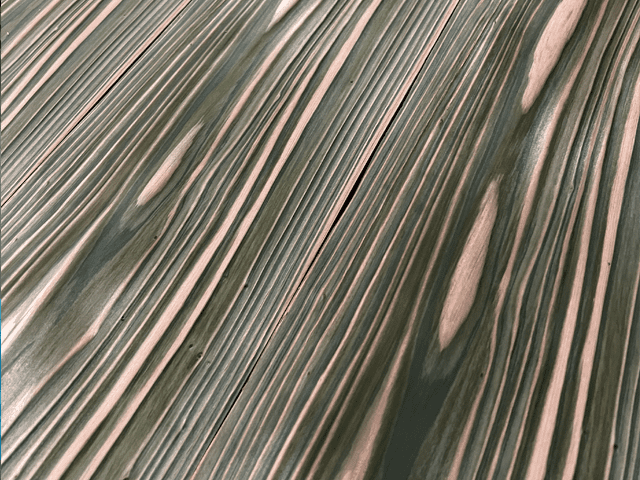

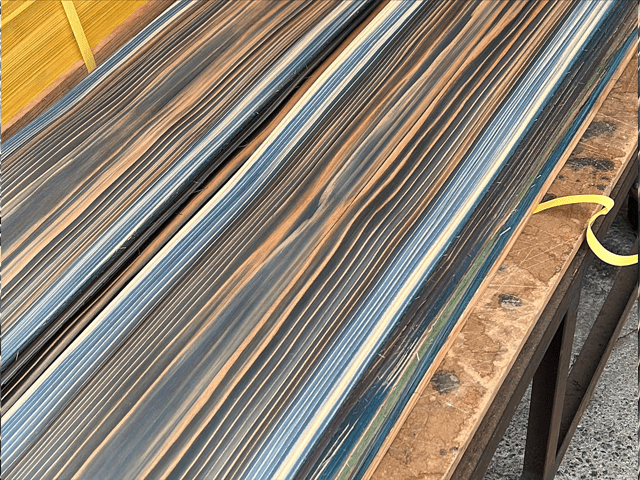

Dyed veneer - IRODORI VENEER- color sample

Instructions

- Please consult about the customer wanting the color except the color mentioned above.

- The above sample color may be different from a real color by the lighting of a monitor and color setting, the room of the PC which a customer uses.

- I have the characteristic that the cedar is easy to be over expectation than a hinoki. (a projecting board waves)

- Because the adherence density of dyestuff is different from the outside of the Dyed wood / Dye penetrated wood in the inside, the wood inside becomes thin.

- Penetration condition of the light and shade, the dyestuff of the color varies according to wood species, dyestuff density, quality of wood of each board.

- As for the cedar, as for other than the black (light blue in particular), the color of the red meat tends to remain.

- For improvement in quality, please note that you may change dyestuff without a notice.

- It is lacking in dyeing, and, by the quality of wood of raw materials, a penetration spot appears. Depending on the number of the square meters, I am not suitable for a wall use.

- An expression is greatly different in equal quality of wood for a production center and the lasting fat of the tree. Please think about the color sample mentioned above and following production example in reference degree.

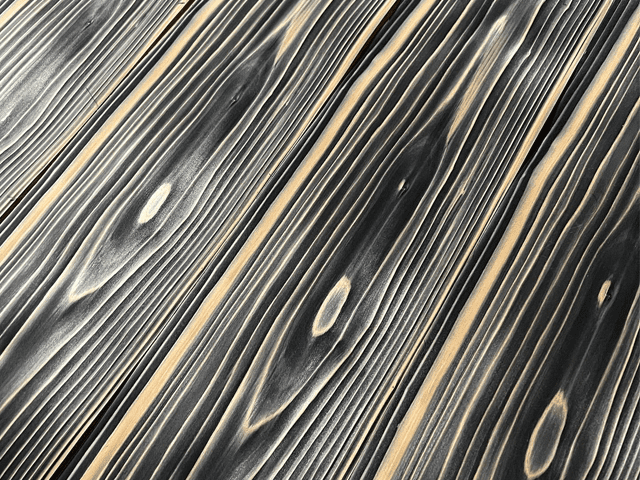

Production example (for ※ reference. The same Wood veneer is never born)

Process of manufacture (in the case of a cedar)

It is a video when I sliced a dyeing black cedar board for the first time. I still challenge it by length of a little over 1m then! I began in here!

Each color is a video when I sliced the cedar board which I dyed. It is a video when I challenged it for the first time other than the black.

It is a video when I slice a cedar board of the dyeing blue and processed it.

Process of manufacture (in the case of a hinoki)

Use example

Round fan

Sunglasses

I have the frame of sunglasses use our dyeing hinoki Wood veneer.

CLOTS HANDMADE IN JAPAN

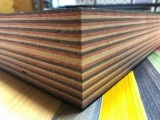

Dyed fancy plywood

An inquiry, the visiting and seeing you calculating, order from here

※Please note that the sample becomes charged.

Product concerned

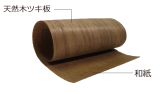

| Wood veneer sum papering (elegant) It is most suitable for curved surface processing. Put Japanese paper; about elegant processing

|

| Dyed fancy plywood The new color panel which I stuck the projecting board which I dyed on as surface dressed lumber.

|

| Dyed veneer laminated wood / blank The color material which laminated and bonded the veneer which I dyed. To interior and a gunstock, a model gun, a knife grip, sporting goods, other tree industrial art objects.

|

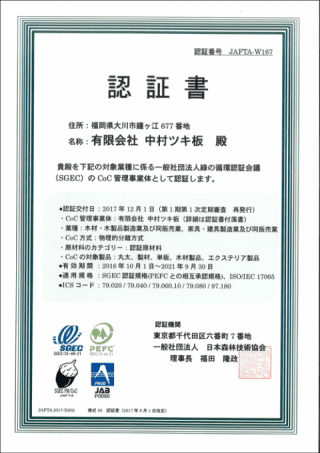

| Fire retardant treated wood production NAKAMURA TSUKIITA INC. "FRT WOOD" only in North Kyushu The Ministry of Land, Infrastructure, Transport and Tourism minister authorization Fire retardant treated wood which I impregnated to a pure cedar, hinoki board with a fire retardant with note.

|

| Dyed wood / Dye penetrated wood Color Wood who infiltrated dyestuff into the wood inside unlike the color system coloration paint.

|

| Dyed veneer The material which dyed projecting board veneer of thickness 0.2~1 around .0mm.

|