Fancy Plywood

This video shows how to make fancy plywood.

Banner to pre-set

Bargain (super special price of the stock limit)

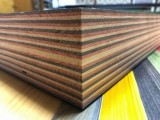

Fancy Plywood / Decorative Plywood

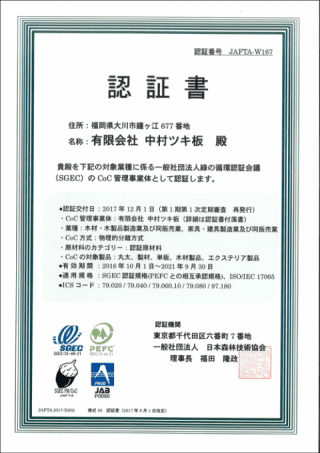

Many people have suffered sicknesses from building materials that use formaldehyde. It often causes dizziness, headaches, and watery eyes. To avoid these situations, An organization called the "Formaldehyde Emission Standards" setup strict guidelines in regards to the safety standards of this chemical. We received the highest rating of 4 stars.

We have various kinds of veneers which come from all over the world but we highly recommend using hinoki (Japanese cypress) or Japanese cedar because the appearance of both are really beautiful. These Japanese species give you a comfortable scent which gives relaxation. So what are you waiting for? Try our fancy plywood now!

Core

①Lauan plywood

Lauan plywood (also known as Luan Plywood) is a commercial term used throughout the Japan that typically refers to a 610*2430mm to 1220*2430mm tropical hardwood plywood panel used for underlayment in flooring, lamination, paper overlay, furniture, and millwork applications..

[Thickness : 2.5mm 4.0mm 5.5mm]

②M D F

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure.MDF is generally denser than plywood. It is made up of separated fibres, but can be used as a building material similar in application to plywood. It is stronger and much denser than particle board.

[Thickness : 2.5mm 3.0mm 4.0mm 5.5mm 9.0mm 12.0mm 15.0mm 18.0mm 21.0mm 24.0mm 30.0mm]

③Lumber core/Block board

Lumber Core plywood consists of a face & back veneer, then a layer of crossband veneer, with the edge glued or finger jointed lumber in the center. Meranti, falcata, pine, rubber wood and other species are used for lumber core.

[Thickness : 12mm 15mm 18mm 21mm 24mm 30 mm]

Size

| Standard size | Width | Length | |

| 1 | 610*2430mm

|

610 millimeters | 2,430 millimeters |

| 2 | 920*1830mm

|

920 millimeters | 1,830 millimeters |

| 3 | 920*2130mm

|

920 millimeters | 2,130 millimeters |

| 4 | 920*2430mm

|

920 millimeters | 2,430 millimeters |

| 5 | 1220*2430mm

|

1,220 millimeters | 2,430 millimeters |

Wood veneer illustrated book

The finish painting

Finish Option

| Remark

| |

1

| Unpainted

| All natural.

|

2

| Urethane painting

| Its surface has a glossy appearance which pronounces more of the natural features.

|

3

| Color painting

| Ask us what colors are available.

|

The process of manufacturing Fancy Plywood

①Suitable sliced veneers are selected

②Veneers are cut into suitable sizes

③Glue is coated on the plywood/mdf by a pasting machine

④Veneeres are pasted on the plywood

⑤They are hot-pressed

⑥Any access material leftover from pasting is cut away

⑧Surface is polished by a wide belt sander

⑨Ready to be packed and delivered!

※Please note that the sample becomes charged.

Product concerned

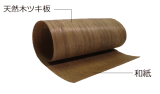

| Wood veneer sum papering (elegant) It is most suitable for curved surface processing. Put Japanese paper; about elegant processing

|

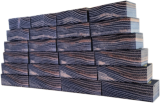

| Dyed fancy plywood The new color panel which I stuck the projecting board which I dyed on as surface dressed lumber. |

| Dyed veneer laminated wood / blank The color material which laminated and bonded the veneer which I dyed. To interior and a gunstock, a model gun, a knife grip, sporting goods, other tree industrial art objects.

|

| Fire retardant treated wood production NAKAMURA TSUKIITA INC. "FRT WOOD" only in North Kyushu The Ministry of Land, Infrastructure, Transport and Tourism minister authorization Fire retardant treated wood which I impregnated to a pure cedar, hinoki board with a fire retardant with note.

|

| Dyed wood / Dye penetrated wood Color Wood who infiltrated dye into the wood inside unlike the color system coloration paint.

|

| Dyed veneer The material which dyed projecting board veneer of thickness 0.2~1 around .0mm. |