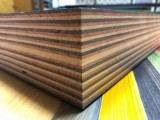

Dyeing Birch veneer laminated wood, laminated plywood

Dyeing Birch veneer laminated wood, laminated plywood - IRODORITAI PLY -

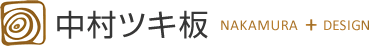

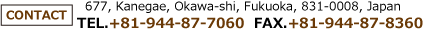

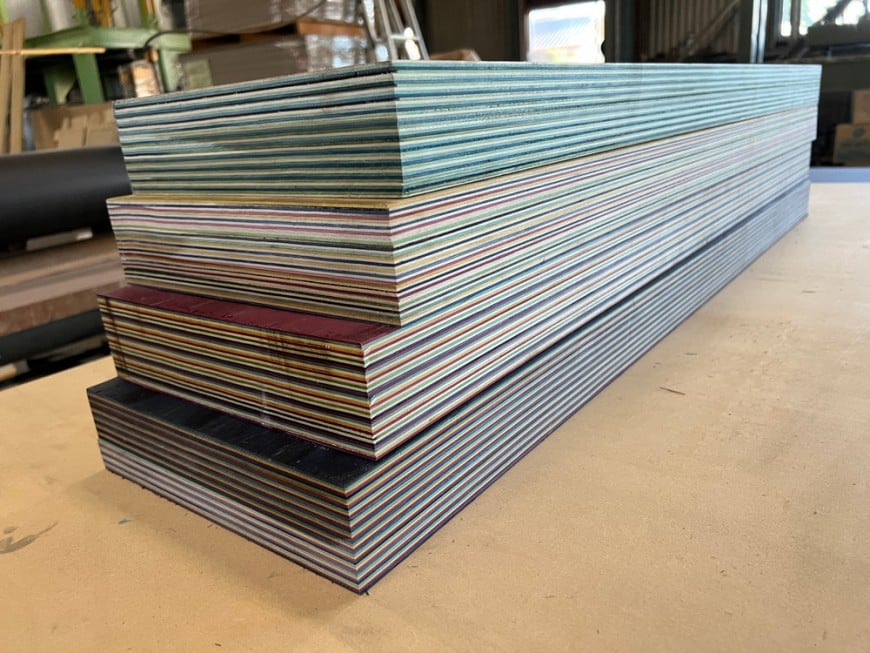

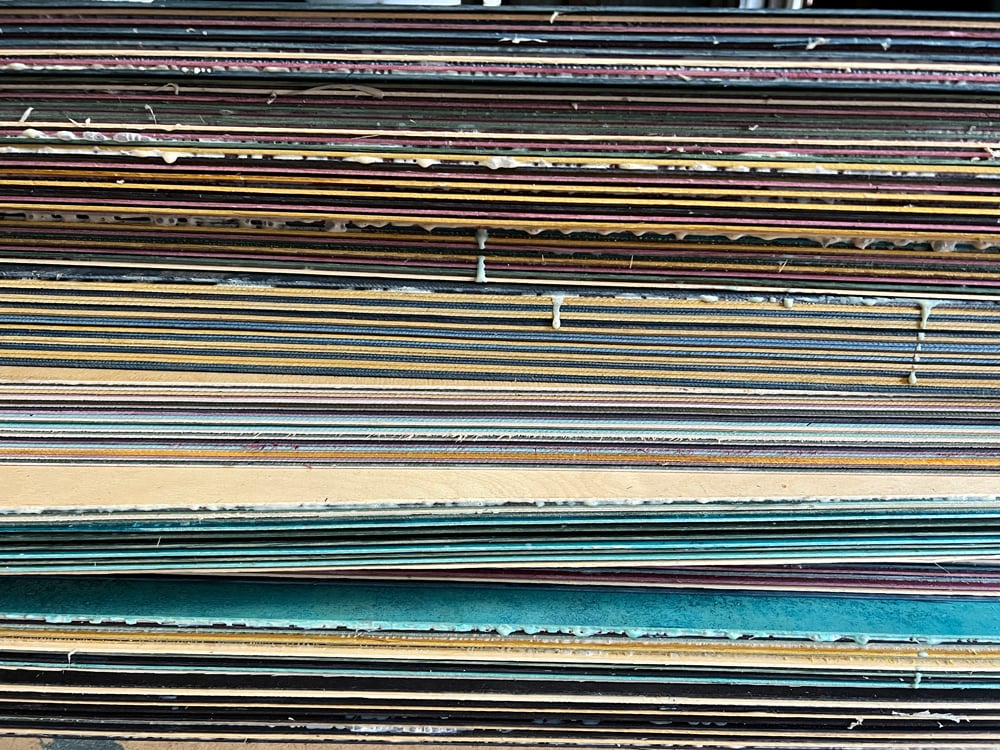

It is original color laminating plywood, laminated wood (LVL) which laminated and bonded the 1.5mm thickness Birch veneer that I dyed. Seeing from the side, pure Kiguchi layer such as the millefeuille is totally the biggest characteristic.

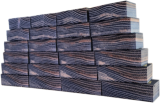

▪ A grain of wood design such as the aestheometry totally appears by making NC processing, lathe processing.

▪ The use varies depending on the ideas such as a model gun, a hand grip, an accent of the furniture, the top plate of the table, a wooden toy, a tree craft.

▪ A grain of wood design such as the aestheometry totally appears by making NC processing, lathe processing.

▪ The use varies depending on the ideas such as a model gun, a hand grip, an accent of the furniture, the top plate of the table, a wooden toy, a tree craft.

The online shop from here → https://tsukiita.thebase.in/

The biggest thickness | Maximum size | Characteristic | |

Dyeing Birch veneer laminated wood (LVL) | 30mm (20PLY) | 1,200*800mm | I laminated and bonded veneer with fiber directions together. As there is not thickness, a risk to bend after the adhesion occurs. |

70mm (46PLY) | 1,000*220mm | I laminated and bonded veneer with fiber directions together. Because there is thickness, there are fewer risks to bend after the adhesion than the thing mentioned above. | |

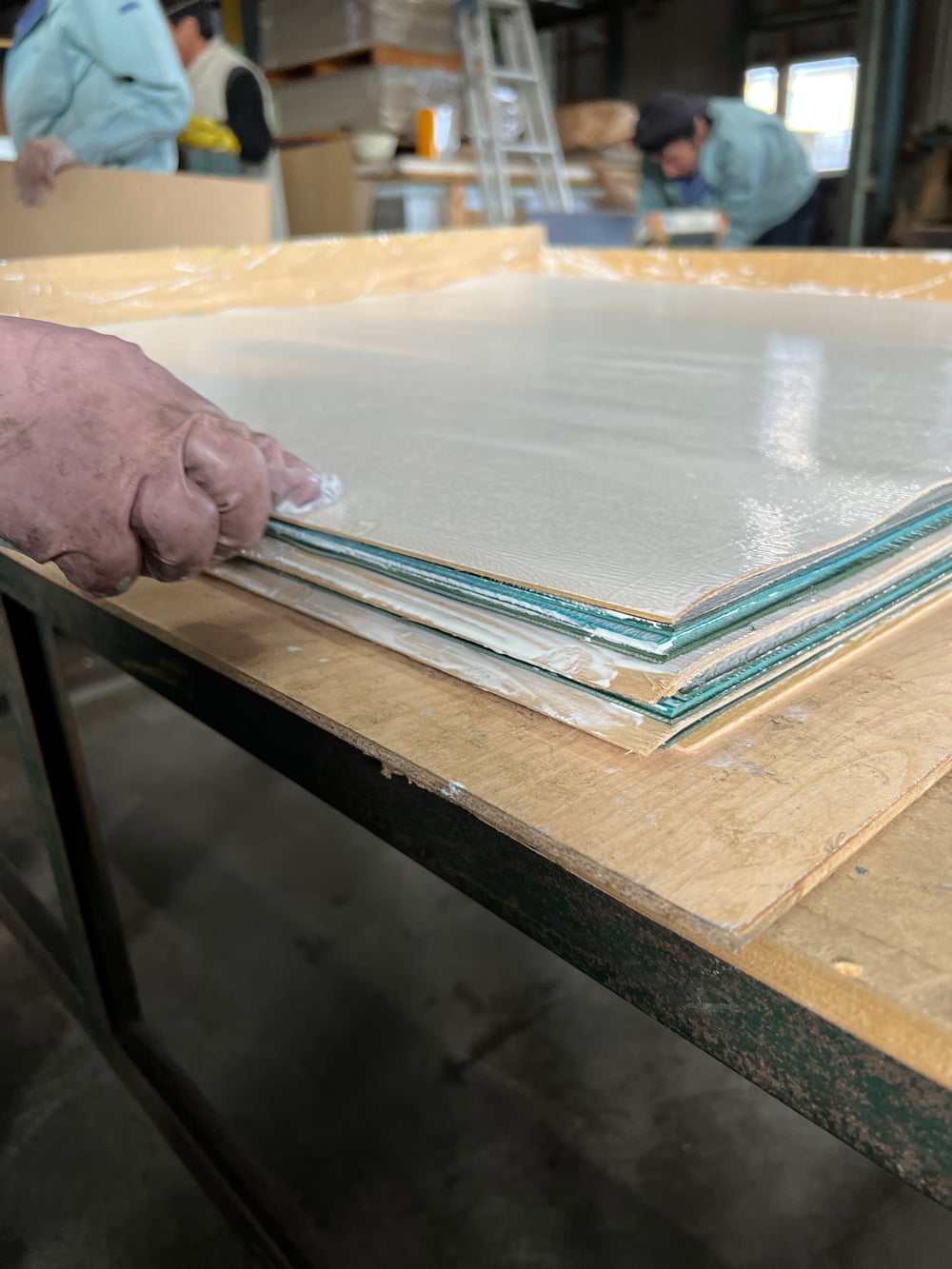

Dyeing Birch laminating plywood | 30mm (20PLY) | 800*800mm | I let the veneer be at right angles to the fiber direction and laminated and bonded it. Therefore there are fewer risks of the curve than LVL. |

The biggest thickness mentioned above is just an indication. When there is thickness you like, please consult separately.

Use example

The video of the potter's wheel leg processing clicks the thumbnail mentioned above↑

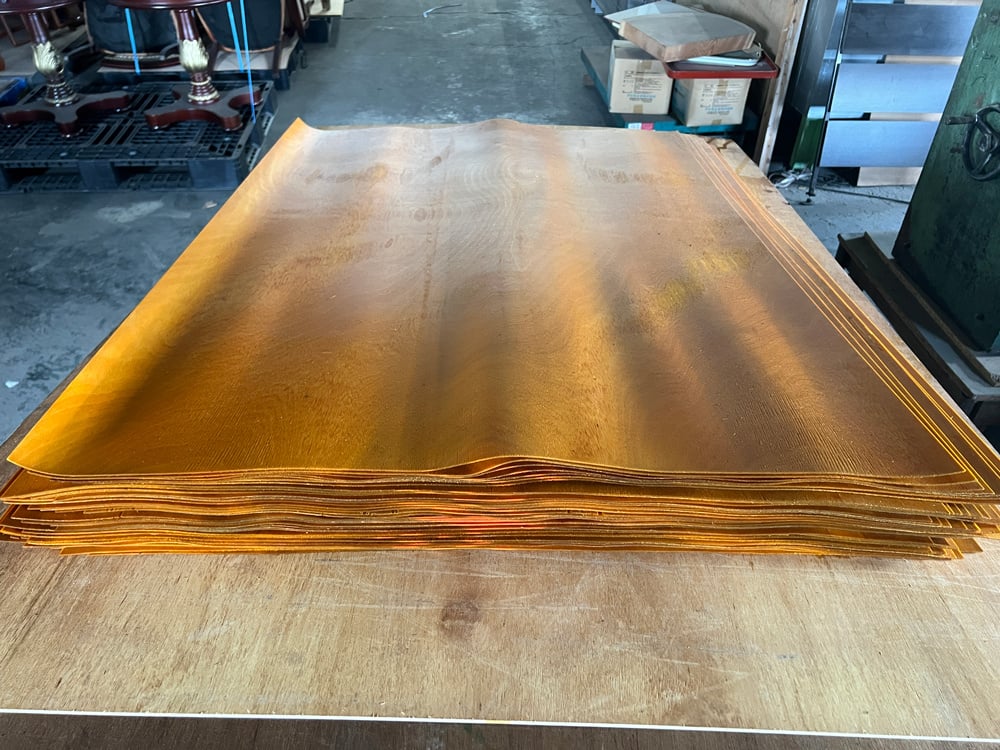

Process of manufacture

An inquiry, the visiting and seeing you calculating, order from this

※Please note that the sample becomes charged.

Product concerned

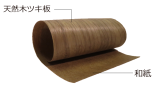

| Wood veneer sum papering (elegant) It is most suitable for curved surface processing. Put Japanese paper; about elegant processing

|

| Dyed fancy plywood The new color panel which I stuck the projecting board which I dyed on as surface dressed lumber. |

| Dyed veneer laminated wood / blank The color material which laminated and bonded the veneer which I dyed. To interior and a gunstock, a model gun, a knife grip, sporting goods, other tree industrial art objects.

|

| Fire retardant treated wood production NAKAMURA TSUKIITA INC. "FRT WOOD" only in North Kyushu The Ministry of Land, Infrastructure, Transport and Tourism minister authorization Fire retardant treated wood which I impregnated to a pure cedar, hinoki board with a fire retardant with note.

|

| Dyed wood / Dye penetrated wood Color Wood who infiltrated dye into the wood inside unlike the color system coloration paint.

|

| Dyed veneer The material which dyed projecting board veneer of thickness 0.2~1 around .0mm. |